[ad_1]

Furnishings Cladding and Self-importance Models

Furniture cladding commonly brings together a quantity of our expert services this kind of as templating, waterjet reducing, mitring, etching, bullnosing, steel inlays and epoxy bonding. The blend of these providers enables designers and dwelling house owners who clad their home furniture and vainness units to commission special and eye-catching furnishings in residences and places of work.

Templating

The first stage of creating cladding for vainness models and household furniture starts with the templating stage. Our design and style team full multiple detailed templates of all the furnishings that is to be cladded, making certain all measurements are proper to the millimetre.

As soon as all on-web-site templating is accomplished, the group get the blueprints back again to their office to develop CAD designs, tidying up the patterns and earning sure all of the templates are accurate. The use of a CAD layout software allows the group to complete any contact ups, change the templates and blend templates to make sure that each and every piece of the cladding will suit precisely.

When all of the templates are finalised, they are despatched to our waterjet slicing amenities to be cut into form.

Fabrications

Most vanity models and furnishings cladding have to have bonding, etching, bullnosing and epoxy bonding. The process each and every self-importance unit have to go by means of is all dependent on the clients’ needs for the piece of get the job done.

For our most modern cladding task, minimal fabrication was needed as the task was to be fitted on-web page by a different crew. Our fabrications workforce adopted the required get the job done to be finished on the work sharpening and ending the edges of the tile to take away any sharp edges and to produce a shiny finish.

This stage was concluded employing diamond sprucing pads and diamond hand pads. If you would like to acquire possibly of these instruments, you should click here.

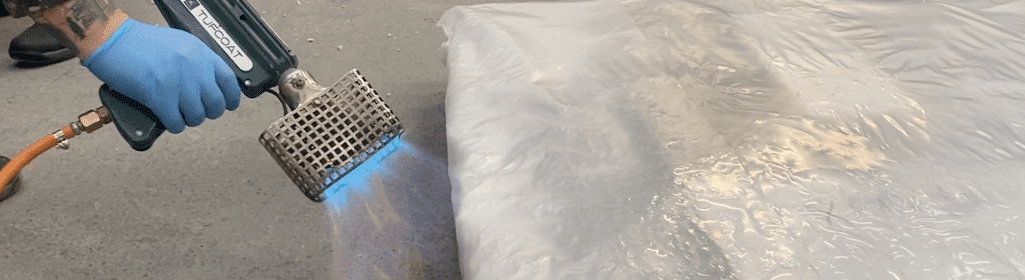

Packaging

When all of the fabrications do the job is complete, the workforce ensure all of the tiles are cleaned ahead of they are ready to be sent. The fabrications workforce total an inspection to guarantee there are no chips, cracks or scratches on the tiles and every little thing is in great ailment completely ready to be delivered.

When we comprehensive our careers at Aquacut, we delight ourselves on our packaging. We produce tailor made packaging/crates to ensure the tiles are guarded all through transit. We often use a mixture of pallets, wooden, packing foams and shrink wraps.

Summary

If you would like to see far more facts on this subject, head above to our YouTube channel where you can come across further information and video clips.

Really don’t fail to remember to check out out our social media webpages such as Instagram and Fb in which we often put up content on all services and areas.

[ad_2]